Welcome to Techdim

Tech-savvy guide through the exciting world of technology at Tech Dimension

We’re here to simplify the complex and make technology understandable for everyone. Whether you’re looking for advice on gadgets, software, or solutions to tech issues, we’ve got your back. Our dedicated team of experts is here to share real-life experiences and provide you with the best and most effective insights. Join us on this journey as we explore the vast dimensions of technology together.

As Featured In

We’re proud to have been featured by some of the world’s leading organizations. These features highlight our excellence in the field of Electronics Knowledge. Here are a few of the organizations that have recognized our work

Browse Categories

Browse Categories

Find Popular topics for your circuit needs:

Recent Blogs

Best 3 Cheapest Data Recovery Software in the Market

Have you experienced a situation where you lost important personal data accidentally or intentionally? This is incredibly painful. However, technology has made it a lot…

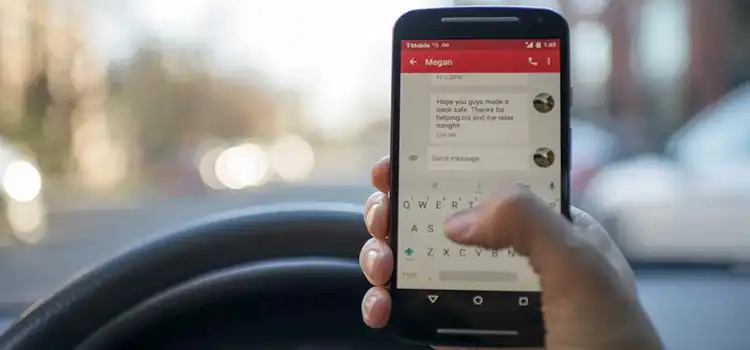

Staying Safe in the Age of Texting | How to Identify and Prevent Text Message Scams

Text messaging serves as a convenient, real-time communication channel connecting people instantly. However, an exponential rise in text scams threatens user security and privacy. Devious…

Is Dawn AI Safe to Use?

You know, when it comes to using AI apps like Dawn AI for creating avatars, I can’t help but wonder about safety and privacy concerns….

Is CoD CPU or GPU Intensive? Explained

Anyone who’s strapped into the boots of a soldier in a Call of Duty (COD) game knows the importance of smooth, responsive gameplay. Whether you’re…

iPhone Country Code List | Explained

I’ll be honest, when I first got my iPhone, the “country code” thing seemed like a total mystery. Just a bunch of random letters and…

Understanding Data Security Posture Management | Securing Digital Assets in the Modern Era

In today’s digital-first world, the security of data has ascended to the forefront of organizational priorities. Amidst the relentless advancement of technology and the ever-expanding…

Crafting Success with a Localized Marketing Strategy | A Comprehensive Guide

In an era marked by globalization and digital connectivity, the allure of tapping into a worldwide market has never been more tempting for businesses. Yet,…

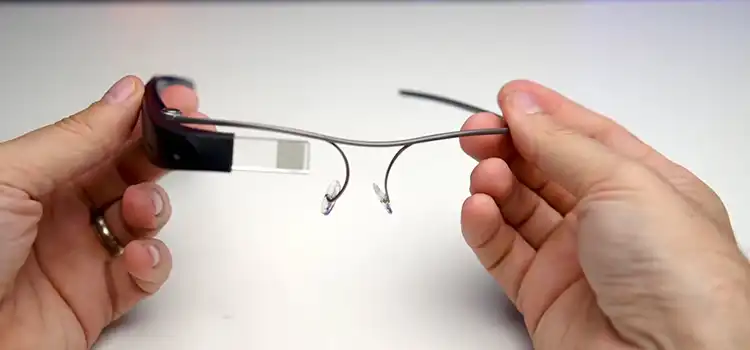

Exploring AI-powered Glasses for Visual Impairment

Advances in artificial intelligence (AI) and wearable technology are converging to create exciting new assistive devices for people with visual disabilities. One innovation showcasing this…

Crypto Hosting is The Next Big Thing and Here is Why

Blockchain and particularly Cryptocurrency is the trend permeating nearly all domains of today’s human digital life. Web hosting, an area that is so important for…

Hardware & Software

- Best 3 Cheapest Data Recovery Software in the Market

- Is Dawn AI Safe to Use?

- 6 Common Mistakes to Avoid When Storing PC Hardware in Units

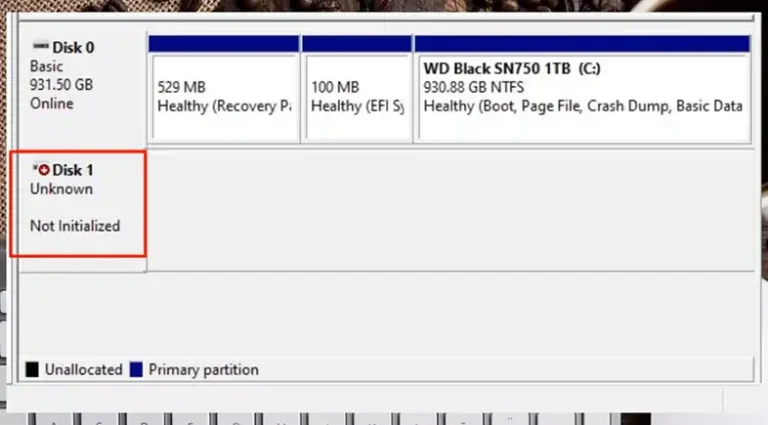

- How to Fix an SSD Not Initialized?

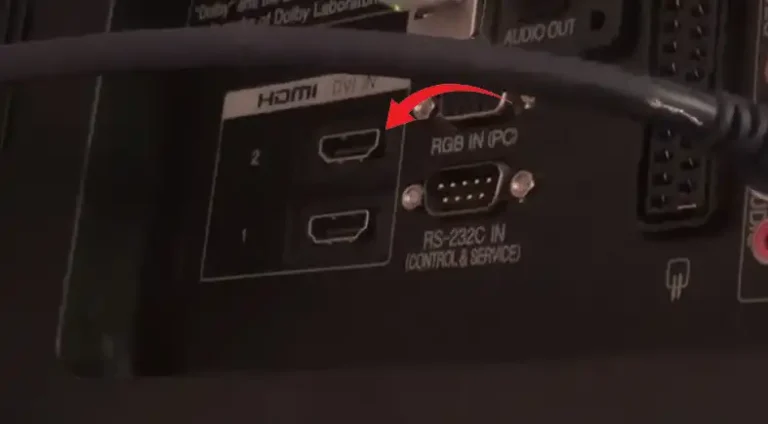

- HDMI Dummy Plug What Is It and How Do You Use It?

- Decoding the Cost of Developing an iOS App_ An In-Depth Analysis

- Enhancing Healthcare IT Service Management with Alloy Software Solutions

- The Link Between Signature Styles and Personal Characteristics

- Can I Put a Graphics Card in Any Slot?

- Should I Be On HDMI1 or HDMI2?

Technology

- Is CoD CPU or GPU Intensive? Explained

- iPhone Country Code List | Explained

- Understanding Data Security Posture Management | Securing Digital Assets in the Modern Era

- Exploring AI-powered Glasses for Visual Impairment

- Crypto Hosting is The Next Big Thing and Here is Why

- How Do I Reset My HDMI Port on My JVC TV?

- Can I Bypass One Connect on Samsung TV?

- Enhancing Healthcare IT Service Management with Alloy Software Solutions

- Touch Screen Problems After Screen Replacement – iPhone 11

- Can I Use 2 Amplifiers on the Same Speaker Set?

Android & Windows

- What Is Carrier Hub Processing Requests?

- How to Check Your Smartphone’s Memory Usage?

- Precision in Every Line: Real-Time Operating Systems (RTOS) in Embedded Software

- What Is Dex2oat Android? A complete walkthrough

- How Cluttered Software Affects Your Phone’s Performance?

- Essential Mobile Tools | The Top 10 Must-Have Android Apps Of 2024

- Does Logitech C310 Work With Windows 10? 8 Considerable Facts

- [Fixed] Class ID 2593F8B9-4EAF-457C-B68A-50F6B8EA6B54 | a Runtime Broker

- [Answered] Can I Delete Log Txt On Android?

- [4 Fixes] computer won’t boot past bios screen

Artificial Intelligence

- Exploring AI-powered Glasses for Visual Impairment

- Content Writing Services: The Key to Your Firm’s Long-Term Accomplishments

- How Much Can a Trading Bot Make?

- Tech Trends: Top 5 Emerging Technologies for Business

- The Impact of Undetectable AI Writers on the Job Market

- Navigating Creativity: A Guide To Writing With ChatGPT

- Google Gemini AI: What is it, and How to Use and It’s Comparison with ChatGPT?

- Does ChatGPT Have Malware? What I Found

- What Is WormGPT? What You Should Know

- WormGPT vs ChatGPT | What Apart Them

Can’t Find What You’re Looking For?

Need Assistance?

Techdim works on –

Simplifying Technology

We simplify technology so everyone can understand it. No jargon or confusion.

Tech Trends

Stay updated on the latest tech trends, gadgets, and DIY projects with our insights and recommendations

Problem-solving

We help you solve your tech issues. From software troubles to choosing the right gadgets, we’ve got solutions

Techdim Numbers

Monthly readers

Tech Guides

Years Online

How Techdim Ensure Quality Content?

At Techdim, a bunch of young tech enthusiasts invest countless hours in researching, experimenting, and fine-tuning every article. Their dedication ensures that you receive accurate, up-to-date, and reliable information.

Expert Opinions

We start with insights from our tech enthusiasts

Thorough Research

In-depth research from credible sources informs our content

Editors’ Review

Experienced editors ensure clarity and readability

Publishing

Only after passing these stages do articles earn their place on our site